Over the years, there have been a lot of arguments and counter-arguments on ABS vs. PBT keycaps. Recently, the topic has continued to be a bone of contention among the community of keyboard enthusiasts and pro-users.

Certainly, both ABS and PBT keycaps dominate the market for keycaps. However, they possess specific mechanical and chemical differences that will influence your efficiency while working or gaming with keyboards.

It’s important to understand the nature of both keycap types to make a sound purchase decision. This article aims to cover everything of importance about ABS and PBT keycaps and draw comparisons.

Contents

PBT vs. ABS Keycaps Comparison Table

| Comparison Factors | ABS Keycaps | PBT Keycaps |

| Durability | Lasts, but not as long as PBT | Lasts long compared to others |

| Cost | Less expensive due to lower production cost | More expensive due to difficulty molding |

| Noise | Produces more unpleasant sound | Produces dull, less unpleasant sound |

| Comfort | Less comfortable to use after wear | Very comfortable to type with |

| Melting Point | 105 degrees | 225 degrees |

| Double Shot Keycaps | Suitable for double shot keycaps | Better for double shot keycaps |

| Weight | Weighs half as a PBT | Weighs twice as an ABS |

| Beauty | Sleek and glossy | Has a textured feel and less gloss |

ABS Keycaps vs. PBT Keycaps: Full Review

Without a doubt, ABS and PBT are the most widely used plastics in the making of keycaps. Thus, they are continually coming up with important updates to enhance performance and user experience.

As we proceed, we will take a look at the keycap components and focus specifically on their features, functionalities, pros, and cons.

1. ABS Keycaps

Pros

- Widely available

- Less expensive

- Easier to mold

Cons

- Produces greasy feel after surface wear

- Produces an unpleasant typing sound

Undoubtedly, most keyboards on the market come with ABS keycaps made of ABS, which is the short form for Acrylonitrile Butadiene Styrene.

Usually, ABS keycaps have a very easy molding process, and the keycaps won’t shrink much during molding.

This ability to maintain a consistent shape explains why ABS plastics are used even in PBT keycaps, where spacebars are made of ABS to prevent shrinking.

Styrene, one of the major substances in the formation of ABS plastics, is what gives the keycaps a shiny, impervious surface after years of use.

Not only is ABS tough, but it also has acceptably high impact resistance. Modification can occur during the formation of ABS plastics by altering the percentages of chemical constituents to make the ABS tougher and more resilient to heat and impact.

Keycaps made from ABS maintain high rigidity and good impact resistance at all times. They have good insulating properties with high dimensional stability. Similarly, ABS keycaps are mechanically strong and stable over time.

One of the major problems commonly associated with ABS is that it scratches easily when it comes in contact with certain chemical substances. ABS keycaps are also very flammable when exposed to high temperatures.

Another disadvantage of ABS is the fact that it is quicker to turn yellow compared to PBT when subjected to UV light over time from sunlight and artificial lamps. Although some top-quality ABS material suffers the same fate, it is more predominant in low-grade ABS keycaps.

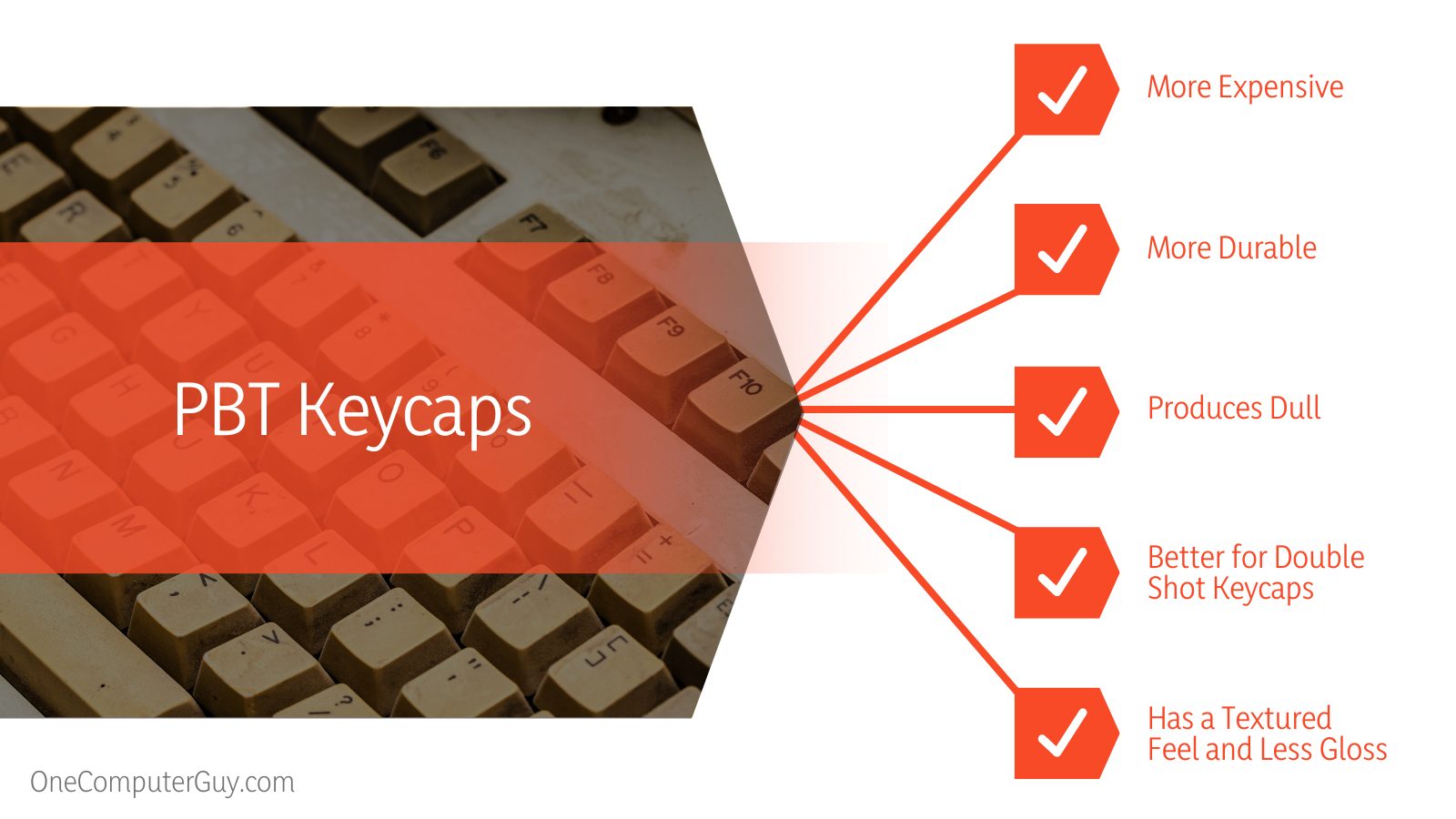

2. PBT Keycaps

Pros

- Shine-resistant

- More durable

- Produces better double shot keycap

Cons

- Expensive and more difficult to mold

- Not very common like ABS keycaps

PBT is among the hardest and most durable components used in the making of keycaps. It is highly resistant to heat and most chemical substances. However, the tough and high-resistance nature of PBT makes it difficult to mold, and therefore more expensive.

Unlike ABS keycaps, PBT can survive frequent exposure to UV lights and other conditions. Since PBT plastics are tough, you can exert pressure on it with millions of keystrokes without fear of cracking or breaking a keycap.

This is one area where it outperforms ABS keycaps. Heavy use of ABS over the years will likely result in wear, where the little tactile bump on the J or F key completely wears off as with other keycaps.

PBT, due to its somewhat complicated manufacturing process and price, is less common than ABS. It is pretty expensive to source.

Because PBT is less rigid and more brittle than ABS, it takes more time to wear down. While this is a great advantage, it is the main reason for the high prices and scarcity.

PBT keycaps can endure three or four decades of use and still look good. Their textured and sandy feel makes PBT less smooth than the ABS.

Comparison Between ABS and PBT Keycaps

The main difference between ABS and PBT keycaps is their difference in sound. They also feel different, with ABS feeling smoother and developing a greasy shine over time. PBT has a textured feel. This shouldn’t imply that ABS is not durable and, therefore, unsuitable for use. It just means it is less durable than PBT.

Keycaps are very important for any computer keyboard due to the critical role it plays in making our work with computers more efficient. They are the little plastic objects that cover the keyboard of your computer.

The names ABS and PBT come from the chemical constituents of the plastics. The chemistry is boring for those who just want to choose between ABS and PBT keycaps, so we’ll shun much of it in favor of concentrating on a few qualities that set ABS and PBT keycaps apart.

Although keycaps are essential to the functionality of a computer, not everyone appreciates just how important they are.

There are several materials from which keycaps are made, ABS and PBT plastics being more common. The difference between ABS and PBT keycaps makes one more suitable than the other for certain preferences.

To appreciate keycaps, imagine typing on your computer without it. That means your fingers will hit the key-switches directly.

What does this imply? Your typing becomes slow, hard, and dreadful. Keycaps indicate the functions of each key-switch and guide you to punch the right one for a desired reaction from the computer. Their absence makes you prone to making too many errors.

The absence of keycaps will make using a computer very costly.It may result in frequently changing damaged key-switches as a result of pressure from keystrokes or external factors like humidity.

Keycaps can be made from a variety of plastics which may undergo different manufacturing processes. The differences in material and production processes are more than what you think. They can go a long way to determine how long a keyboard will last before you need to replace it.

That’s why I think it’s super important to know the stuff a keyboard’s keycaps are made of and what the implications are before purchasing one.

Unlike ABS keycaps, PBT keycaps are less common and much tougher. They take forever to wear out, and that’s why they don’t change color like ABS over time. The downside of PBT keycaps is the price tag, brittleness, and scarcity.

Anything that’s more expensive than its peers most likely becomes scarce as more people shy away from expenses. Expenses are a significant source of stress.

Manufacturers who saddle people with overly expensive products often struggle to persuade consumers. It’s happening with keycaps, too. Both ABS and PBT do the job well, but the manufacturing process for each plastic differs. PBT is more difficult and less cost-effective.

Not all ABS plastics have inferior quality. Some inferior ABS keycaps can have faded legends in a matter of two years, depending on the frequency of use. Others made with a greater determination can last over a decade.

Different chemical substances combine in certain percentages to form both ABS and PBT plastics. The specific percentage of each substance contained is what results in quality differences.

ABS keycaps will also start to thin over time. Its smooth surface makes it easier for your fingers to glide across the keycaps. This greasy and shiny development on the surface is due to exposure to conditions that gradually change the color of the keycaps to yellow.

They tend to be thinner than PBT keycaps, though there are good quality ABS keycaps that are as thick as any PBT. Being thick has the advantage of added strength.

At times, when a particle of sand or some object gets stuck under your keycaps, you have to remove the keycaps to get rid of the object. At this point, thin keycaps are far more likely to break than thick ones.

– Weight

Irrelevant as it may seem, the weight of keycaps matters plenty provided typing experience is of importance. The heavier a key, the smoother and more reliable its response. Lighter keys are slower in response to key strikes.

Compared to PBT, ABS keycaps are typically lighter—about half as heavy. If you prefer a smoother and more enjoyable typing experience, PBT is the keycap for you. For some reason, if you prefer a light keycap, then go for ABS.

– Noise

If you don’t like noisy keycaps, steer clear of ABS keycaps, especially the thin ones. The materials from which ABS is made, the keycaps produce clicking noises as you type.

This can be a distraction or even an embarrassment, particularly when working in a quiet environment like libraries. Both keycap types produce some kind of noise, but PBT typically produces less noise than ABS keycaps, even for thin PBT keycaps.

– Durability

Whoever is spending money on a product wants it to last. As PBT is made from a more reliable material, it is sturdier and lasts longer than ABS. The keycaps maintain shape for longer. ABS keycaps get dents and wear comparatively faster.

Because ABS is less resistant to pressure, it’s more vulnerable to cracking from keystroke pressure. This makes the likelihood of early replacement is higher than that of PBT keycaps.

– Melting Point

This is important because there are people who make their own keycaps. The melting point of materials for keycaps is important.

ABS plastics are known to melt at about 105degrees, while PBT melts at 225 degrees, making ABS keys easier to mold. Due to a high melting point, molding your own PBT takes longer to cool and is more likely to warp.

– Double-Shot Keycaps

The double-shot molding method is a leading tech skill in the formation of keycaps because key labels aren’t likely to wear off.

These are formed when two separate plastic pieces are molded into one, allowing for the legend to be printed on the inside of the keycaps and unlikely to wear off while typing.

Double shot ABS keycaps still produce shiny surfaces, but the legend never wears off. On the other hand, double shot PBT keycaps have the added advantage of a protected legend and consistent surface. It makes even more interesting clear PBT keycaps.

Conclusion

Overall, your choice of keycaps will greatly depend on your personal preference, as higher-end keycaps from both options are bound to deliver excellent performance.

However, from what we’ve seen so far, PBT keycaps are better than ABS keycaps despite some disadvantages in cost and molding. Unlike the ABS keycaps, they have a stronger, textured build that enhances durability, longevity, and overall performance.

PBT keycaps also show remarkable resilience in the presence of UV lights, heat, and other chemical substances.

While the predominant choice of keycaps favors PBT, some people prefer ABS for one reason or another. What matters most is for you to get a first-quality keycaps set, whether ABS or PBT.